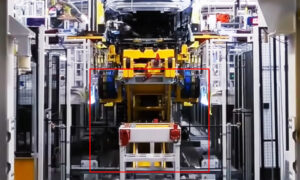

了解边缘计算工作站与电流传感器的安装

汽车总装车间升降机故障预测方案

预测性分析系统通过非侵入式电流监测与AI算法,实时感知总装车间升降机运行状态,识别传动、导向等关键部件的早期劣化,实现故障预警与健康评估,提升设备可靠性与产线连续性。

看得见的智能制造:设备状态可视化解决方案

我们提供标准化且可定制的预测性分析大屏展示方案,基于自采高频电流数据,集中呈现设备健康状态与预警信息。不仅实现对产线动态的统一监控,更让智能化成果“看得见”,有效提升工厂形象,赢得管理层与访客认可。

汽车焊装车间机器人故障预测方案

预测性分析系统通过非侵入式电流监测与AI算法,实现对焊装车间机器人关键部件的早期故障预警,提前2~6周识别伺服电机、减速机等劣化趋势,降低75%非计划停机,提升设备可靠性与生产效率。

玻璃搬运机器人故障预测方案

该文介绍了先端领航为玻璃制造研磨线开发的搬运机器人健康监测方案,通过非侵入式电流信号采集与AI算法,实现早期故障预警、按需维护,显著降低停机与玻璃破损率,提升产线OEE,助力智能制造升级。

预测性分析系统边缘端部署案例

关于预测性分析系统的边缘端部署,采用“一机一柜”模式,通过定制化工控机与多通道电流传感器实现本地采集与AI分析,支持4G/有线双模联网,具备免改造、快部署、全轴监测等优势。

汽车冲压机故障预测方案

该方案介绍了测性分析系统在汽车冲压机智能运维中的应用,通过非侵入式电流信号采集与人工智能算法,实时监测设备运行状态,识别关键部件的早期劣化趋势,实现故障预警与健康评估,从而提升冲压车间的运行稳定性、设备可靠性与生产效率。

手机后盖热压机故障预测方案

预测性分析系统在手机后盖热压机上部署,通过1000Hz高频采集主电机电流信号,无需接入PLC,实现对液压异常、电机过载等故障的早期预警。应用后非计划停机减少76%,OEE提升至91.3%,产品不良率下降67%,助力制造商实现高效稳定生产。

手机贴片机故障预测方案

工业设备预测性分析系统通过实时采集贴片机多源运行数据,结合AI模型实现早期故障预警与健康评估,帮助手机制造商降低非计划停机74%,提升OEE至93.7%,推动高价值产线从被动维修迈向智能运维。